Key Takeaways

Individual agents (5-10% commission) suit small orders, agencies provide structured support for growing businesses, and full-service providers (8-12%) handle complex regulated products.

Check business registration through Chinese government databases, request current client references, and start with a trial order worth $5,000-$10,000 to test performance.

Orders above $20,000, products requiring compliance, or businesses without Mandarin speakers benefit from agent expertise. Simple standardised products under $5,000 can be sourced directly through platforms.

Language barriers, cultural differences, and supplier verification difficulties create risks that can derail your China sourcing supply chain strategy.

China sourcing agents bridge this gap by acting as your local representative in China. They handle supplier verification, negotiate pricing, manage quality control, and coordinate logistics on your behalf and give you access to reliable Chinese suppliers.

Agents provide access to manufacturers that won't work with first-time importers directly and help businesses avoid costly mistakes from quality issues or supplier fraud. Their local expertise and established relationships enable better pricing terms than most buyers can negotiate independently.

This guide covers the types of China sourcing agents available, where to find them, how to evaluate their credentials, and what to expect from the relationship.

Explore: Sourcing depends on scale: small firms need 1–100 units, while large enterprises require multiple factories or specialised partners. Learn more about how to import from China in 7 steps.

What is a China Sourcing Agent?

A China sourcing agent is a professional intermediary who represents your business interests when working with Chinese manufacturers. Unlike trading companies that buy and resell products, sourcing agents work on your behalf throughout the procurement process to source products without taking ownership of goods.

Sourcing agents operate as your local representative in China. They communicate with suppliers in Mandarin, understand local business practices, and navigate cultural nuances that can create misunderstandings for foreign buyers.

Core services include:

- Supplier identification and vetting

- Price negotiation

- Quality control coordination

- Production monitoring

- Logistics management

Agents provide essential infrastructure for businesses without Chinese language skills, manufacturing expertise, or local contacts. They streamline the sourcing process and help you understand how they differ from other sourcing options:

How sourcing agents differ from other options:

| Option | How It Works | Cost Structure |

|---|---|---|

| Sourcing Agent | Works on your behalf, doesn't own inventory | 5-10% of order value or fixed fees |

| Alibaba/Platforms | You manage supplier relationships directly | Platform fees, no intermediary costs |

| Trading Company | Buys wholesale and resells to you | Product markup (often 15-30%+) |

When to Use a China Sourcing Agent

When Agents Add Maximum Value

- First-time importers benefit most from agent expertise. Without experience in Chinese manufacturing, language barriers, cultural differences, and supply chain complexities create significant risks. Agents reduce the learning curve and prevent costly beginner mistakes.

- Complex products requiring technical specifications, quality testing, or regulatory compliance justify agent costs. Electronics, medical devices, food products, and items with safety certifications need expert oversight that platform-based sourcing cannot provide.

- High-value orders above $20,000 warrant professional representation. The 5-10% agent commission becomes proportionally smaller whilst the risk of quality issues or supplier fraud increases significantly.

When You Might Not Need an Agent

- Simple, standardised products available from multiple suppliers on Alibaba may not require dedicated agents.

- Items like phone cases, simple apparel, or commodity products with established specifications can be sourced directly using platform protections like Trade Assurance, maximising cost savings by eliminating agent commissions.

- Very small trial orders under $5,000 often don't justify agent fees. Use these small orders to test direct sourcing capabilities before scaling up with agent support.

Value Calculation: If potential quality issues could cost you 20-30% in returns or replacements, the 5-10% agent fee provides strong ROI through prevention.

Types of China Sourcing Agents Compared

China sourcing agents operate under different business models, each suited to specific business needs and order volumes.

Individual Freelance Agents

Independent agents work solo or with small teams, offering personalised service and direct communication. They typically charge 5-10% commission, often at the lower end due to reduced overhead, making them a cost-effective option for smaller businesses.

Best for:

- Small businesses and startups

- Order values under $50,000

- Close, direct relationships

Quality depends heavily on the individual's experience and network, and capacity limitations may emerge as your business scales.

Sourcing Agencies

Agencies employ multiple agents and support staff, providing structured processes and backup coverage. They charge 5-10% commission depending on order complexity and volume.

Best for:

- Growing businesses with consistent orders

- Multiple product categories

- Reliable continuity

Larger networks provide diverse supplier access, though you may experience less personalised attention than with individual agents.

Platform-Based Sourcing Services

Services like Alibaba's Trade Assurance offer automated supplier vetting and payment protection at no additional cost to buyers.

Best for:

- DIY-comfortable buyers

- Simple, standardised products

- Low cost sourcing with broad supplier access and basic protection

Limited hands-on quality control or negotiation assistance compared to dedicated agents.

Full-Service Providers

These companies combine sourcing with product development, quality testing, compliance certification, and logistics management. Commission rates typically fall in the 8-12% range.

Best for:

- Complex products (electronics, medical devices, food)

- Regulated industries requiring compliance

- Comprehensive support needs

Selecting the Right Type

Your choice depends on order volume, product complexity, and internal capabilities. Small first-time orders suit individual agents or platforms, whilst growing businesses benefit from agency infrastructure more robust supply chain management. Complex or regulated products require full-service expertise regardless of order size.

Where to Find China Sourcing Agents

Finding a reliable sourcing agent requires searching beyond simple Google queries. Multiple channels offer access to qualified agents, each with distinct vetting requirements.

Online Platforms and Directories

Professional sourcing platforms like Alibaba's service marketplace, Upwork, and specialised B2B directories list agents with client reviews and verified credentials. LinkedIn provides access to independent agents and allows you to review their professional backgrounds and client recommendations.

|

Quick Verification Checklist:

|

Industry Associations and Networks

Trade associations specific to your industry often maintain recommended agent lists. Organizations like the China Chamber of International Commerce or industry-specific groups vet members and can provide introductions to reputable agents.

Business networks and entrepreneurship communities focused on sourcing from China, frequently share agent recommendations. However, always conduct independent verification regardless of referral source.

Trade Shows and Sourcing Events

Canton Fair, Global Sources exhibitions, and industry-specific trade shows in China provide opportunities to meet agents face-to-face. Many agents attend these events specifically to connect with potential clients.

Meeting agents in person allows you to assess professionalism, communication skills, and factory network access. Request factory visits during trade show trips to evaluate their relationships with manufacturers.

|

Red Flags When Vetting Agents

Avoid agents who:

|

Industry Associations and Networks

Trade associations specific to your industry often maintain recommended agent lists. Organisations like the China Chamber of International Commerce or industry-specific groups vet members and can provide introductions to reputable agents with established networks of Chinese suppliers.

Business networks and entrepreneurship communities focused on China sourcing frequently share agent recommendations. However, always conduct independent verification regardless of referral source.

Trade Shows and Sourcing Events

Canton Fair, Global Sources exhibitions, and industry-specific trade shows in China provide opportunities to meet agents face-to-face. Many agents attend these events specifically to connect with potential clients.

Meeting agents in person allows you to assess professionalism, communication skills, and factory network access. Request factory visits during trade show trips to evaluate their relationships with manufacturers.

How to Evaluate Sourcing Agents

Thorough evaluation separates reliable agents from those who will cost you time and money. A structured vetting process reduces risk before committing to partnerships.

Critical First Step: Request a detailed service agreement before any payment. This document should outline fees, responsibilities, quality standards, and dispute resolution procedures. No agreement means no deal

Verify Essential Credentials

Request business registration documentation from Chinese authorities. Legitimate agents operate registered companies with verifiable addresses, not just virtual offices or PO boxes. Cross-reference registration details through China's National Enterprise Credit Information Publicity System.

Confirm physical office presence through video calls showing their workspace, or better yet, visit their office if attending trade shows in China. Agents should provide clear documentation of their business structure and legal standing.

Experience and Track Record

Evaluate experience in your specific product category and request case studies or examples of similar products they've sourced. Ask about their product quality control processes and how they ensure high-quality manufacturing standards.

Ask for client references , if possible, and actually contact them. Recent references matter more than testimonials from years ago.

Factory Network Assessment

Request details about their supplier network. Reliable agents maintain established relationships with multiple manufacturers in your product category, not just connections to trading companies or middlemen.

Testing Factory Access: Ask the agent to arrange video factory tours for 2-3 potential suppliers. Genuine agents can organise visits to Chinese factories within days. Delays or excuses suggest limited factory access.

Communication and Transparency

Evaluate responsiveness during initial inquiries. Agents who take days to respond before you're a client won't improve after.

Request a detailed fee structure in writing. Transparent agents clearly outline commission rates, additional service fees, and payment terms upfront without hidden charges.

Start with a Trial Order

Test performance with a small order worth $5,000-$10,000 before scaling up. This reveals their actual capabilities in supplier negotiation, quality control, communication, and problem-solving when issues arise.

Evaluate whether they proactively identify potential problems or only react when you discover issues. Strong agents catch quality concerns before products ship.

Tip: Always conduct your own due diligence by requesting samples, checking references, and verifying business licences independently before committing to large orders.

Working with a China Sourcing Agent

The Typical Workflow

Here is an estimated timeline for working with sourcing agents:

Initial Consultation: 1-2 weeks

Sample Procurement and Approval: 2-4 weeks

Final Terms and Production: 4-8 weeks

Quality inspections occur at multiple stages: pre-production (raw materials and setup), during production (in-line checks), and pre-shipment (final inspection). Agents provide detailed reports with photographs at each checkpoint.

Communication and Reporting Expectations

Establish clear communication protocols from the start. Most agents provide weekly updates during production, with daily communication available for urgent issues. Expect responses within 24 hours during business hours (China time).

Note: Supplier evaluation should include factory audits, sample prototyping, and verification that manufacturers meet relevant local or international quality standards.

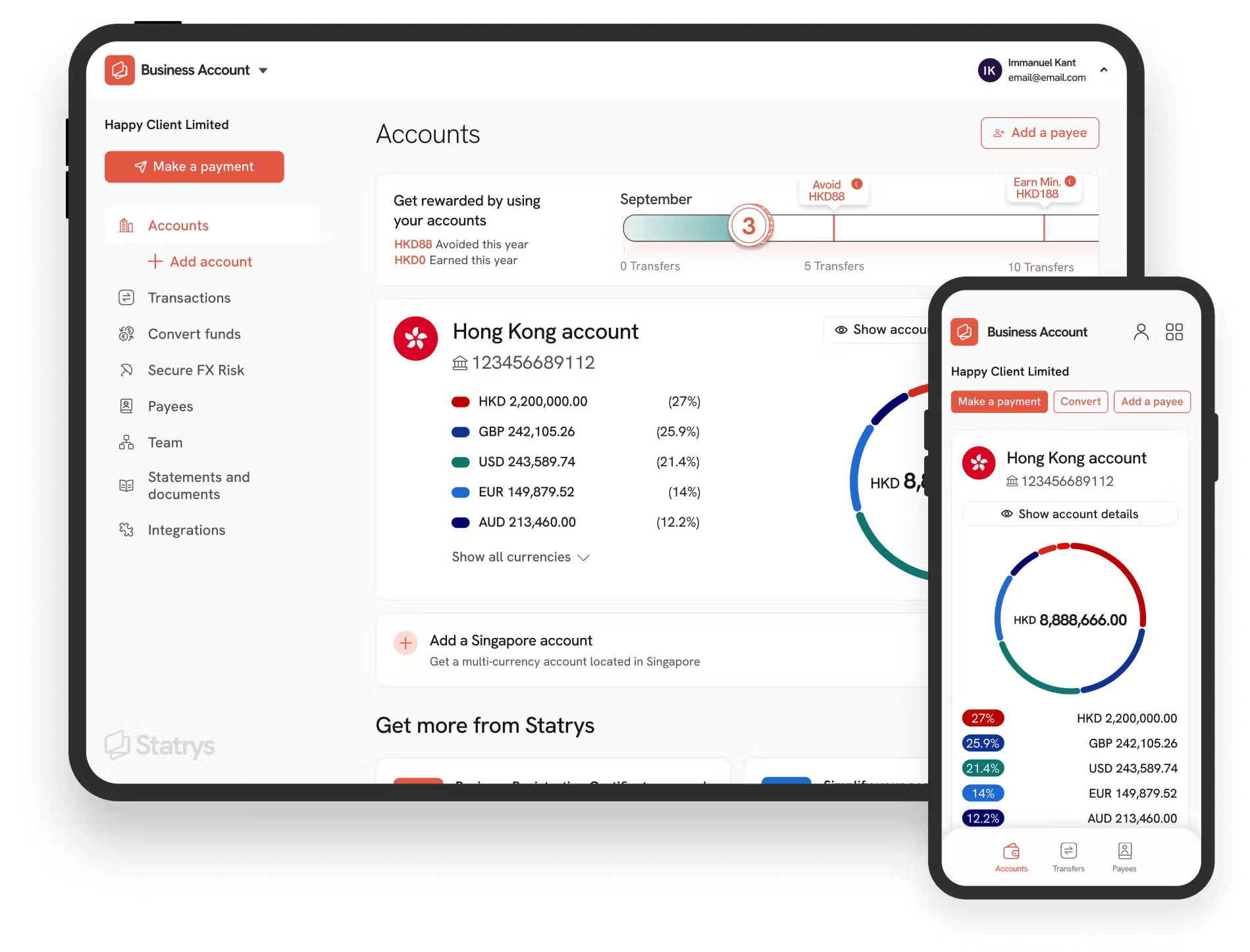

Make Payments to China Simple

Using a Hong Kong multi-currency business account enables you to pay in RMB, reduce foreign exchange FX costs, and simplify reconciliation. With a Statrys Hong Kong multi-currency account, you can hold, send, and receive payments in multiple currencies, including RMB (Chinese Yuan).

Was this article helpful?

Yes

No

FAQs

How much do China sourcing agents charge?

Most China sourcing agents charge 5-10% commission on order value. Individual freelance agents typically charge at the lower end, whilst full-service providers charge 8-12% for complex products requiring compliance support. Some agents also offer flat fees for specific services.