Have you been working on a new product idea that you’re ready to bring to market, but you aren’t sure how to find manufacturers? You’re not alone. A Harvard Business School professor estimated that more than 30,000 new consumer products launch every year. That means there are plenty of manufacturers that can turn your idea into a reality — but that doesn’t mean they’re all going to be a good fit.

In this guide, you’ll learn how to find, evaluate, and partner with a manufacturer either in your country or abroad. Whether you need to find a Chinese manufacturer that can handle large orders or you want to work with a domestic factory, this article will help you get started.

The process takes some time, but it’s pretty straightforward:

- Start researching manufacturers

- Contact manufacturers with questions

- Get quotes

- Request and evaluate samples

- Sign a contract and place an order

- Monitor progress and evaluate finished products

1

Start Researching Manufacturers

Researching manufacturers is the first step in bringing your idea to market. It can be a long and complex process finding the right fit because you’ll need one that can meet all your requirements— from physically manufacturing your products to packaging and shipping them.

There are several ways to start researching manufacturers, including via:

- Referrals: Check with people you know to get firsthand information about the manufacturers and suppliers they use (and the ones they avoid). Social media platforms and online forums are also useful. You can join industry-specific LinkedIn and Facebook groups where members share their experiences.

- Google Search: You can try searching on Google using terms like “manufacturers near me” or “factory near me” to find local options. Then, visit their websites to see if their products and services align with your needs. Make sure to read customer reviews to get an idea of their quality and reliability before making a decision.

- Directories: Online supplier directories exist to help people just like you find manufacturers. Some of these databases are curated, meaning the suppliers listed have been vetted for quality, while others are like digital bulletin boards where any company can upload their information.

- NAICS codes: If you’re in North America, you can use the North American Industry Classification System to look for companies that manufacture products in your industry. Both the US and Canada have directories to make searching easier.

- Trade Shows/Expos: Look for manufacturer expos or industry-specific events in your field. These are excellent opportunities to meet and connect with manufacturers and suppliers, and view product samples.

Platforms to Find Manufacturers

Here are some platforms where you can find manufacturers. It's important to review the manufacturer carefully before making a decision.

Resource | Industries Served |

Packaging, home decor, furniture, apparel, and accessories made in the US | |

Household goods, consumer electronics, pets, fitness and health, textile and apparel, toys, and automotive | |

Over 6 million industrial and nonindustrial products in the US | |

Multiple categories Alibaba is a popular platform that helps you find ready-made products or work with manufacturers, primarily located in China, to develop custom items. The platform is popular for ecommerce and dropshipping | |

Multiple categories IndiaMART is the largest online directory and marketplace in India, helping manufacturers, suppliers, and exporters connect and conduct trade with one another. | |

Global Sources | Multiple categories Multichannel B2B online marketplace and sourcing platform that connects buyers with verified suppliers and manufacturers. |

A website that lists British manufacturers by category. |

Choosing the right manufacturer also depends on the specific product category you're dealing with. Furthermore, identifying red flags and risks is another important part of your research. While there’s no guarantee that even the most reputable companies will deliver perfect products, reputation is a good indicator of what you’ll get. Here are a few tips for evaluating suppliers:

- Check resources like the Better Business Bureau (in the US), Yell (in the UK) and online review sites.

- Talk to people in the industry to learn about their experiences with different companies.

- Make sure the manufacturer isn’t a trading company — trading companies are middlemen, not manufacturers.

Once you have a few manufacturers you think could work, it’s time to reach out to learn more.

Tip: Check out this article to learn everything you need to know about finding Chinese suppliers and sourcing from China.

3. Get Quotes

After you’ve received responses from prospective suppliers, choose the ones that seem like the best fit and request quotes. During this stage, you may need to share your designs or prototypes with the manufacturer in order to get an accurate quote. But beware — sending designs to suppliers, especially if you have unique and proprietary designs, increases your chances of intellectual property theft, so be very selective about who you share your designs with. If necessary, see if the manufacturer is willing to sign a confidentiality agreement before you send them the designs.

Evaluating quotes is important, so take your time. A few elements to look for include:

- Cost per unit: Now that the manufacturer has your design, they should be able to provide you with a fairly accurate per-unit cost. If you want a price break, request a quote on several quantities because prices decrease as the number of units produced increases.

- Minimum order quantity (MOQ): A manufacturer’s MOQ will give you an idea of the quantities they’re used to dealing with.

- Freight costs: Check these fees against the answers the supplier provided during your initial contact. While shipping rates fluctuate, the two figures should be close.

- Setup fees: This is another line item to compare to the first communication. If new tools or processes need to be created to make your product, the setup fee will probably be higher than the original estimate.

Now that you have several quotes, it’s time to compare them. You’ll need to decide on the balance between cost and quality to ensure you’re selling a product your customers will be happy with and also helps you make a profit. Once you’ve narrowed your options, it’s time to see what these manufacturers can do.

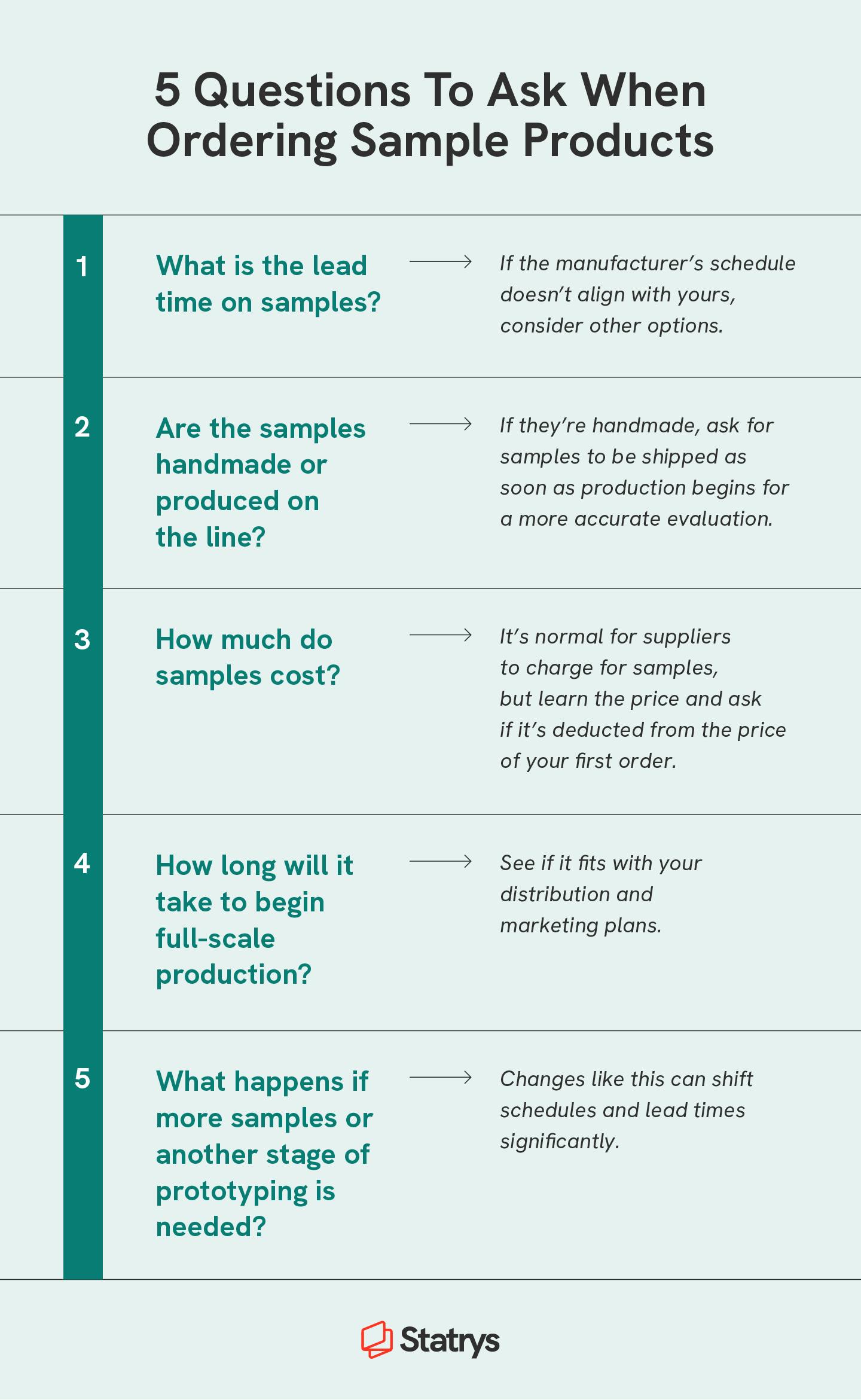

4. Request and Evaluate Samples

After you’ve considered the quotes from prospective suppliers, choose the ones that seem like the best fit and request samples from them. Many manufacturers will require you to pay for samples, but they may subtract the price from your first purchase.

Once you receive the samples, dive deep to make sure everything is how you want it. Check that they look and feel right and that they function appropriately. Comparing them directly to your plans and prototypes can help you distinguish between manufacturing issues and problems with the design.

If you need to make changes, be as specific as possible when communicating with the manufacturer. If you have to update components or a part of the overall design, send them the new plans and prototypes so there is no mistaking which version of your product they are going to produce.

If you’re satisfied with the quality of the samples, keep them safe so you can use them as the baseline for the full production run. Any major differences should be dealt with as soon as possible and in accordance with the process you agree to with the supplier when you’re finalizing contracts.

2

Contact Manufacturers With Questions

Your first contact with manufacturers should be as direct as possible to show that you’re serious and that you understand how the process works. It’s better to send an email than to call, but if you can’t figure out who to email, reach out by phone for some guidance.

The questions you should ask will vary depending on your unique needs, but here are a few to get you started.

- Do you take custom orders? Not all manufacturers are equipped to retool to accommodate requests outside of their normal operations or usual product categories. Some only handle white labelling, providing generic products that multiple companies can tweak and brand as their own, while others may offer private labelling, where they produce more personalised products for a company to sell under its own brand.

- What are your lead times? Lead time is how long it takes to make and ship your order. Depending on the nature of your business, you might need a supplier who can make and deliver products in weeks or you may be fine with a lead time of several months.

- What is your defect policy? If a manufacturer isn’t willing to shoulder some of the cost of defective products, you probably don’t want to work with them.

- What is your production volume capacity? Ask the manufacturer about their ability to handle the volume you need. This would be critical if your business grows or if you're planning to launch a large initial order.

- Do you grant exclusive rights? If you're in a competitive market, having exclusive access to a manufacturer can give you a big edge. You can ask about absolute exclusivity or regional exclusivity.

- Do you have sustainability and ethical practices in place? Working with ethical and sustainable manufacturers isn’t just good for the supplier’s employees and the environment — it can be a selling point for your products. You can check if the manufacturer holds specific certifications, such as SA8000, for ethical labour practices.

Your first email is not the time to share your designs with potential manufacturers. They should be able to answer most, if not all, of these introductory questions without needing to know every detail of your items.

3

Get Quotes

After you’ve received responses from prospective manufacturers, choose the ones that seem like the best fit and request quotes. During this stage, you may need to share your designs or prototypes with the manufacturer in order to get an accurate quote.

But beware — sending designs to suppliers, especially if you have unique and proprietary designs, increases your chances of intellectual property theft, so be very selective about who you share your designs with. If necessary, see if the manufacturer is willing to sign a confidentiality agreement before you send them the designs.

Some manufacturing companies offer product development services like prototyping and 3D modelling, but these can be expensive. To reduce costs, use sketches, written instructions, or reference photos to convey your ideas. Alternatively, hire industrial designers, product designers, or CAD experts, or work with a local designer for prototypes and custom moulds.

Evaluating quotes is important, so take your time. A few elements to look for include:

- Cost per unit: Now that the manufacturer has your design, they should be able to provide you with a fairly accurate per-unit cost. If you want a price break, request a quote on several quantities because prices decrease as the number of units produced increases.

- Minimum order quantity (MOQ): This is the smallest amount of a product that a factory is willing to produce in a single purchase, often hundreds or even thousands of units. In some cases, manufacturers may be willing to negotiate a lower MOQ, particularly if you agree to a higher unit price.

- Freight costs: Freight costs refer to the expenses involved in transporting goods, especially in bulk. These costs can be substantial for international shipments, as they include customs duties and tariffs. Manufacturers typically provide an estimate. While final charges may vary slightly due to fluctuating shipping rates or unforeseen surcharges, they should align closely with the estimate. Any significant discrepancies could point to errors or hidden fees.

- Setup fees: Depending on the product, some items may require the creation of new tools or processes for manufacturing. In such cases, suppliers may charge a setup fee to cover the work involved in preparing their equipment to produce your product.

- Payment terms: Many manufacturers require new businesses to pay for full orders upfront; however, you can ask if other flexible payment options are available. For instance, you could request a 50/50 arrangement: 50% paid upfront and the remaining 50% upon receipt of the shipment.

It's best to compare multiple quotes and find the right balance between cost and quality. This ensures you're offering a product that satisfies your customers while still allowing for a profitable margin. It's important not to sacrifice high-quality production just to lower costs.

Tip: We recommend obtaining at least three quotes to evaluate your options.

4

Request and Evaluate Samples

After reviewing the quotes from prospective suppliers, choose the ones that seem like the best fit and request samples from them. Many manufacturers charge for samples, but they often deduct the cost from your first order.

Once you receive the samples, inspect them to ensure they meet your expectations. Check that they look and feel right and that they function appropriately. Comparing them directly to your plans and prototypes can help you distinguish between manufacturing issues and problems with the design.

If you need to make changes, be as specific as possible when communicating with the manufacturer. If you have to update components or a part of the overall design, send them the new plans and prototypes to avoid any confusion about which version will go to the production process.

If you’re satisfied with the sample quality, keep them safe as a reference for the full production run. Address any significant differences promptly and follow the agreed-upon process with the manufacturer when finalising the contract.

Tip: After reviewing samples, you can still negotiate payment terms or MOQ. However, focus on building a long-term, mutually beneficial relationship rather than just pushing for the lowest price.

5

Sign a Contract and Place an Order

Once everything is ready, you should start finalising the contract. Working with a manufacturer is a collaboration, so try to compromise where you can without affecting your vision or standards. If you get to this stage and the supplier is unwilling to be flexible on contract terms, you can always consider other options.

Whether you’re writing a contract or the manufacturer has sent a contract, it’s a good idea to work with an attorney who has experience in your industry or with manufacturing. An attorney can help make sure your IP and investment are protected.

Some key items to include in a contract are:

- Order Quantity

- Materials

- Cost per unit

- Confidentiality

- Overrun/underrun

- Setup and tooling fees

- Freight fees

- Delivery deadlines

- Defect policy

- Payment schedule

- Reorder process

Once both parties agree and sign the contract, manufacturing can begin.

6

Monitor Progress and Evaluate Finished Products

As production goes into full swing, stay in touch with your manufacturing partner for progress updates. Find out how they want to communicate during this time so you aren’t causing delays. If you plan a site visit, arrive ready to evaluate products. Keep the lines of communication open with your team members in case you need their expertise while you’re on a site visit.

If early production samples were part of your contract, check them as soon as they arrive for any problems that need to be corrected before the entire run is completed. If there is a problem, follow the process laid out in the contract for correcting them.

When you receive the full order, inspect each item or take a random sample to check for any issues.

How To Choose Between Domestic vs. Overseas Manufacturers

Where you source your products is a big decision, and it starts with choosing domestic or international manufacturers. Both options have their pros and cons, so you’ll need to dig deep to find a supplier that will help you strike a balance between low per-unit prices and high product quality.

Here’s a quick comparison between domestic and overseas manufacturers:

Criteria | Domestic Manufacturers | Overseas Manufacturers |

Cost | Costs vary depending on the country, influenced by factors like labor rates, regulatory requirements, and raw material expenses. | In countries like China, India, or Vietnam, production costs are generally lower thanks to their economies of scale. |

Production capacity | The production capacity is shaped by the country's infrastructure, technological capabilities, and market demand. | Depending on the country. Countries with a well-established manufacturing sector, such as China, have vast production capacities. |

Communication | Easy to communicate and visit the manufacturing site | Possible language barriers, harder-to-visit site |

Production Speed | Fast shipping, quicker turnaround times | Longer lead times due to distance |

Product Variety | Limited options, depending on the resources in the country | Many manufacturers to choose from |

IP Protection | You should be able to impose strong IP protection according to your country’s law | Enforcing IP protection across countries can be more complicated |

Supply Chain Flexibility | More predictable, easier to manage | Longer shipping times, subject to international delays |

Risk of Currency Issues | No currency exchange issues | Risk of currency exchange problems |

Freight Costs | Generally lower shipping costs | May be more expensive due to longer distances |

In some cases, producing some goods domestically and others internationally can help you keep costs down while keeping quality high. While this does require more careful planning, the benefits could make it worthwhile.

For example, if you’re an entrepreneur or a business owner in the USA, importing components from China to be assembled in the United States gives you more oversight over the quality of the finalised product for a much lower price than having your goods produced solely in the US.

Tip: If you're working with local manufacturers, we recommend arranging a tour of their facilities or visiting their office to get an inside view of their operations.

Manufacturers vs Suppliers

Manufacturers and suppliers serve distinct functions within the supply chain. Manufacturers produce finished products, such as apparel or electronics, by converting raw materials into market-ready goods that are sold to retailers, wholesalers, or directly to consumers. For example, a clothing manufacturer would craft garments by cutting fabric and adding components like zippers and buttons.

In contrast, a supplier is a broader term that refers to any entity providing products or inventory. While all manufacturers are technically suppliers because they supply goods to businesses, not all suppliers are manufacturers. Suppliers can also include wholesalers or distributors who don't produce goods but offer them as inventory for sale.

Common Issues & Solutions with Manufacturers

Selecting and working with a manufacturer comes with risks that can impact your business. Here are key issues to consider:

Issue | Solution |

Quality Control Issues: Inconsistent quality control can lead to defective products, customer dissatisfaction, and brand damage. | Set clear quality control standards and conduct regular audits and inspections to maintain product quality. The contract should also specify actions for defective products, including replacement or refund, and whether the seller covers return shipping costs. |

Supply Chain Disruptions: Delays in production or shipping, particularly from overseas suppliers, can disrupt the timely delivery of goods. | Consider sourcing from multiple reliable manufacturers or nearshoring to reduce risks and ensure consistent delivery schedules. |

IP Protection: Intellectual property laws can be complicated, especially in certain regions. This increases the risks of counterfeiting or misuse of your proprietary designs and information. | Use strong contracts, including non-disclosure agreements, non-compete agreements and more. |

Communication Barriers: Language differences, time zone issues, and cultural misunderstandings can cause miscommunication and delays in production. | Use translation tools or hire translators to reduce errors and improve efficiency. |

Hidden Costs: Unexpected expenses like shipping, customs, tariffs, and exchange rate fluctuations can strain your budget. | Identify and account for all hidden costs (e.g., tariffs, shipping) in advance to avoid budget surprises. |

Location & Logistics: The manufacturer’s location affects lead time, shipping costs, and logistics, which can impact the efficiency of your operations. | Choose manufacturers closer to your target market to reduce shipping times and costs, and make it easier to oversee production. |

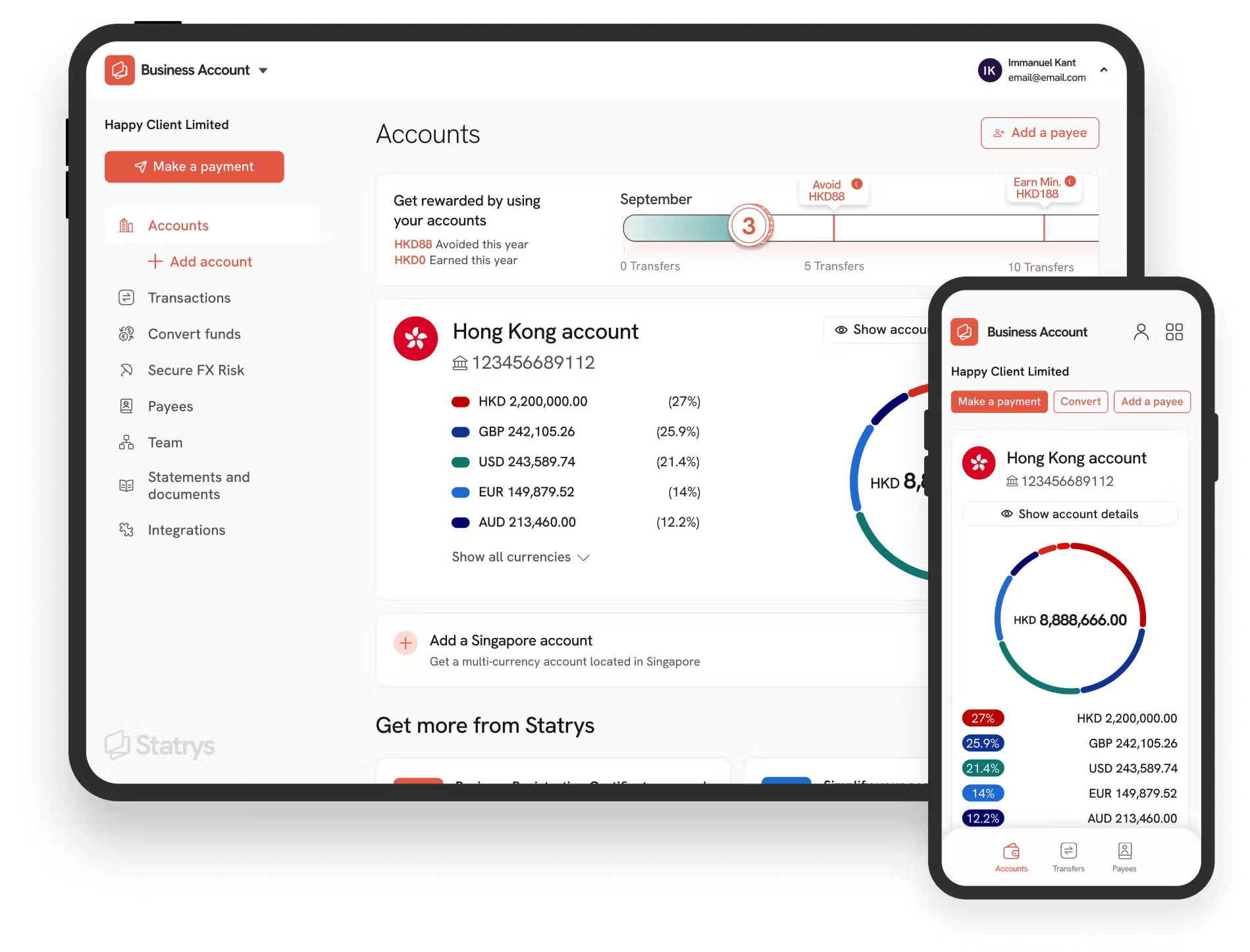

Payment Challenges: International transactions may be substantial and may involve delays due to currency fluctuations, fees, and complex payment processing. | Use platforms designed for international transfers, like Statrys, for smoother, faster, and more cost-effective payments. A provider with multi-currency accounts and FX options can be highly beneficial. |

How Statrys Can Help

Now that you know how to find manufacturers, whether you’re starting a clothing brand or you’ll be selling B2B products online, your company might benefit from opening a business account to make paying manufacturers and suppliers faster and easier.

Statrys is a payment service provider supporting businesses registered in Hong Kong, Singapore, and the BVI, enabling them to send and receive cross-border payments.

Statrys offers a multi-currency business account that supports 11 major currencies, allowing you to hold, send via SWIFT, or use local payment systems that let you pay like a local with lower fees. You can also convert funds when exchange rates are favorable, and take advantage of FX options.

Learn more about the features of Statrys’ business accounts below.

FAQs

What are the types of manufacturing?

There are six main types of manufacturing: • 3D printing • Repetitive • Discrete • Job shop • Continuous process • Batch process Each type is particularly suited to certain types of products and industries.